How A Sri Lankan Apparel Maker Successfully Used E-Fit Simulation

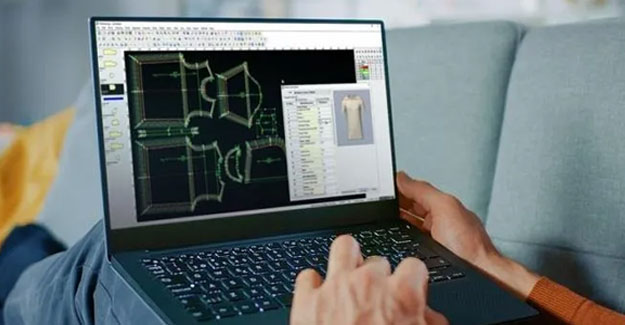

Good Practices in the Global Apparel Industry Garment factories lose a lot of time getting the fit of the garment approved by the buyers. In some cases, buyers send physical samples through couriers to the manufacturers and, in turn, manufacturers must send multiple physical samples to buyers, involving huge cost and time. E-fit simulation allows the garment manufacturers to share 3D-simulated garments for fit approval with the buyers. This reduces the need for multiple iterations of sample approval and results in significant time savings. It also helps provide enough time for production of the garments. The E-Fit Simulator takes digital patterns and turns the pattern pieces into ‘virtual cloth’ that can be ‘sewn’ in the computer and tested on a 3D fit model, right in the software, showing exactly how the garment is going to look before sewing it as a physical sample. With accurate virtual prototyping, the garment fit to the 3D fit model reflects and combines the attributes of the garment style, garment pattern design, and mechanical properties of textiles. Resources/preconditions required E-fit simulation requires the following preconditions when a software is used:

- Buy-in must be created for the team to accept the new technology

- Appropriate software and IT hardware with good processing speed for fast results.

- Reduction in sample development and approval time

- Obtain instant feedback from the built-in motion simulator to correct mistakes immediately

- Convenient to present the test garment and receive comments from anywhere

- Modelling on different body shapes and sizes is possible

- Significant reduction in cost involved in sample making and shipping by courier

- Smaller ecological footprint due to less waste generation and lower CO2 emissions.

- Sample approval rate

- Sample turnaround time

- Pre-production lead time

- A research team was formed to understand the challenge of rapid sample development and ways to address it.

- The team concluded that usage of E-fit software can significantly reduce the sample development time and cost, and would help the company to increase its sample development capacity.

- After careful consideration, the company acquired E-fit software from Tukatech Inc. and staff members were trained in its usage. Some of the other developers providing 3D CAD systems are Gerber, Lectra, Browzwear, Optitex, Cloe and Assyst-Bullmer.

- A few styles from their buyer were requested with technical and fit model specifications.

- As per the specifications of the fit models, the virtual models were created using the CAD system. These 3D models were an exact replica of the buyer’s fit model.

- E-fit software also allowed them to analyse the fabric behaviour. It uses real physical properties of cloth, including the flexibility, stretch, shearing, weight, air resistance and other features.

- A 3D simulator was used to arrange the patterns on the 3D body form. Once the patterns were balanced, they were virtually stitched on to it.

- Using fit mapping, the fit of garment was tested on the model for different activities like running, dancing, posing, walking, etc. using the built-in feature of full-motion simulation. The problem areas were analysed and changes were made accordingly.

- The files were then sent to the buyers to review the fit. Buyers were able to see the garment in 3D and could comment on any style or fit-related changes and, after incorporating the changes, samples were approved. Since the virtually developed samples could be reviewed by the customers without the need for specialised software, the process became relatively easy to adopt.

- After the initial success with a few buyers, the system was rolled out to other buyers.

- There has been a dramatic increase in the number of patterns that the normal pattern makers could make in a day. A team of 15 pattern makers used to develop patterns for 25 styles/day on average. This increased to more than 45 styles/day, leading to an increased number of styles created in a season, making almost 1,000 new styles per month.

- It allowed the users to see how the garments would look on their fit model and the way the clothes drape under stationary and moving situations in real time. This significantly eased the approval process and buyers did not have to use a ‘fit model’ for the sample approval process.

- Since the sample development lead time was reduced and sample accuracy improved, sample approval rate improved, and the buyer gave the company additional styles for development.

- It was possible to do 90% of the work involving physical sample development through the E-fit simulation software. This efficiency gave them a huge increase of business (approximately 40%).

- The Timex team reduced the original product design time per style from three days to half a day in many cases;

- Improved sample approval rate resulted in the company gaining new business from its customers;

- The company’s own brand, Avirate, which started in 2010, benefited from E-fit simulation. “We currently produce about 300 styles every two months, and that is something we could not do without the E-fit solution,” said Arshad Sattar, Director of the company. The company now uses system-generated images and videos for product promotion and selling online, producing garments after they have been sold. This has helped the company to eliminate its inventory of unsold garments.

- Timex invested in eight stations of 3D software, costing a total of approximately $200,000.

- The company estimates that this investment was paid back in less than one year due to savings from sample courier charges and two to four weeks of time reduction in product development, faster sample approval rate and additional business generated.

- Top management’s commitment is crucial for successful technological upgrading.

- There must be a reliable and committed technology partner to address the initial difficulties that those factories face during the introduction of new solutions.

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.