Product Circularity: R-Strategies And The Need To Reorganise

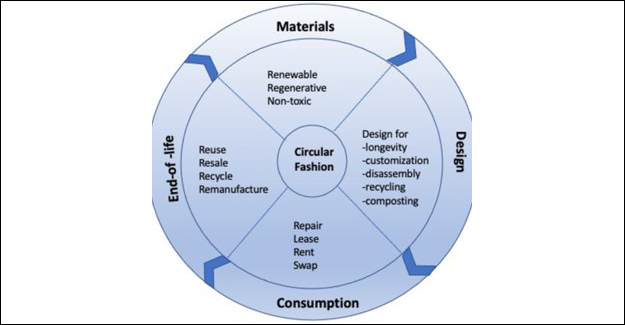

We are aiming for an economy that is 100% circular by 2050. As piles of wasted clothing are growing everyday and less than 1% of current textile production is circular, there is unprecedented urgency to change sourcing models, design strategies and production systems in the fashion, apparel, textile and footwear sectors. While consumers, investors and policymakers have an important role to play in this transition process, companies are expected to take centerstage, and leverage available powerful frameworks to help with their task and elevate the circular economy. With two product cycle pathways and all five of the renowned R-Strategies featured in the Cradle to Cradle Certified Product Standard, companies have the opportunity to learn about circular products, system methodologies and related requirements through this science-based standard. In particular, the Cycling Systems pillar of the Product Circularity category is a valuable resource to get started on these topics. The Standard references “Reuse, Repair, Refurbish, Remanufacture and Recycle” (also known as the R-Strategies) as technical cycling pathways In a technical cycle, a product’s materials or parts are reprocessed for a new product use cycle via one or more of the R-Strategies. Conversely, in the biological cycle, materials or parts are released, and ideally reprocessed via composting, biodegradation, nutrient extraction, or other biological metabolic pathways. “Most apparel, textile and footwear companies presently focus on the technical cycle of product circularity. There are also great initiatives and innovative approaches to designing for the biological cycle. A combination of the two cycles may be the optimal solution: to design products so that they are kept as long as possible in the market, potentially through different users and purposes, and their materials can end up as nutrients to nature,” said Nienke Steen, Sector Lead for Apparel, Textile & Footwear at the Cradle to Cradle Products Innovation Institute. Business models are steadily making way to new approaches where longevity and durability become essential qualities of a product Rooted in the consideration that we should not allow products to go to waste quickly if they are still of value to the market, these approaches are captured as part of new product design strategies in the Standard, and primarily interlace with the R-Strategies of Reuse and Repair, while also having an impact on Refurbish, Remanufacture and Recycle. As part of these new approaches, it becomes increasingly important to engage with consumers, digital platforms and service providers, and create new data driven business models like Recommerce, Renting and Product as a Service. Recycling challenges The Cradle to Cradle Certified Product Standard requires that recycling is always a designated cycling pathway for products intended for the technical cycle, because it is not possible to endlessly reuse and repair them. However, current recycling systems mainly result in downcycled products, like apparel that ends up in textile waste bins to be recycled into fillings or cleaning cloths of lower value. According to the European Commission’s Joint Research Centre's (2021) publication "Circular economy perspectives in the EU textile sector", there is significant potential to reduce textile waste and ensure that it creates further value by boosting its preparation for reuse and recycling. Up to 2.1 million tonnes of post-consumer clothing and home textiles are separately collected each year in the EU for recycling or sale on global reuse markets, representing approximately 38% of textiles placed on the EU market. The remaining 62% are thought to be discarded in mixed waste streams. From the 38%, a lot of garments meant for 2nd hand sale (reuse) end up in big piles of mainly synthetic materials in developing countries. Recycling of materials usually results in post-consumer and pre-consumer content that comes back in the cycle. Post-consumer cycled content is material that has been owned and mostly used by consumers. This can be generated by end-users such as households, commercial, industrial or institutional facilities. Pre-consumer cycled content consists of material or parts diverted from the waste stream during or after a manufacturing process. The widespread uptake of post-consumer material for textiles is generally challenging, since textile materials mainly consist of blends (a mix of raw materials) including labels and trims that need to be detached easily. Sorting technologies are developing, but not yet ready to sort and extract all the different processed raw materials. Most recycling systems depend on the input of clean mono-materials, free from coatings, prints, labels and trims. Moreover, it is difficult to know and test the exact content of the original post-consumer textile materials and what chemical residues are left in it. Using safe materials to cycle is a prerequisite per the Cradle to Cradle Certified Material Health requirements, another core pillar of the Cradle to Cradle Certified Product Standard, next to Product Circularity, Clean Air & Climate Protection, Water & Soil Stewardship, and Social Fairness. Cycling content whose source is not known poses the risk of introducing hazardous chemicals in the product cycle. Knowing the sources, the raw materials and the wet processing treatments, makes it much easier to test and avoid such risk. Therefore, using chemically or mechanically recycled materials from controlled sources makes the Cradle to Cradle Certified assessment much easier. Upcycling In the circular economy, the aim is to extend the lifetime of a product and, when it comes to the end of life, to upcycle and reuse textile “waste” as actual nutrients, to create products of equal or more value to the market, from garment to garment, from plastic waste to shoe sole, from textile to table, or from button to brooch. An example of a product that upcycles post-consumer cycled content is the Napapijri’s Cradle to Cradle Certified Gold Circular Series, an outerwear collection made entirely from chemically recycled polyamide (like fishnets from the ocean), resulting in ECONYL®. It has the same properties as brand new nylon and can be recycled, recreated and remolded again and again. New products can be created without having to use new resources. Aquafil, the company producing ECONYL®, formed an international network structured around recovering materials at end of use. This system allows Aquafil to collect quantities of waste for regeneration into ECONYL® yarn. Another example comes from manufacturers Flamingo Fashion and Shahi, who have designed their Cradle to Cradle Certified Gold level collections for recyclability in partnership with fashion brand C&A. Future outlook for apparel, textile and footwear The apparel, textile and footwear industries have the opportunity - and the ability - to activate the creative and commercial mindset needed to create future business models that take advantage of such waste, full of sources. Cycling post-user content would undoubtedly benefit the circular economy, but is still challenging in an era where tools such as tracking chips, blockchain and digital product passports are not yet widely available to provide detailed information about the supply chain and processing steps per item. However, we are now moving fast in this direction, with new technological and commercial developments, as well as new legislative proposals. The EU Strategy for Sustainable and Circular Textiles, is a prominent example of new legislative initiatives whose proposals range from Eco Design to Green claims requirements, to Digital product passports, to the Extended Producer Responsibility (EPR). EPR, for example, holds producers accountable for the waste that their products create. The requirements entail separate collection of waste and its subsequent management in line with the waste hierarchy. EPR also incentivizes product design that promotes circularity throughout the material life cycle and takes account of the end of products’ life. Several EU Member States, including the Netherlands and France, already introduced EPR requirements for textile companies, given the obligation under EU waste legislation to establish separate collection of textile waste by 1 January 2025. In conclusion, delivering smart design and high quality in products while making use of the cycles and R-Strategies is an essential start in the creation of a circular product. The missing R There is however a R missing in the R-strategy framework: to make the story complete and actionable on a larger scale, we need to “Re-organise” ourselves for active cycling. To make cycling happen, we need to close the cycle chain. Brands and retailers may team up with suppliers, customers as well as transport, repair, sorting, (re)cycle and composting partners. We need to better understand what sorting techniques can do and what recyclers need in order to mechanically or chemically cycle products or components, as they need to learn about the minimum quality requirements of spinners, yarn or fabric suppliers. And that is all related to what we put into the system. That's where the designer comes back in. The designer must be supported and driven by a holistic and equitable company strategy, which in turn needs the support of investors and policymakers. All actors inside and outside the value chain cycle are called to proactively cooperate.In 2050 we need to be operating fully circular, so let’s get re-organised together, today. (C2C Products Innovation Institute News)

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.