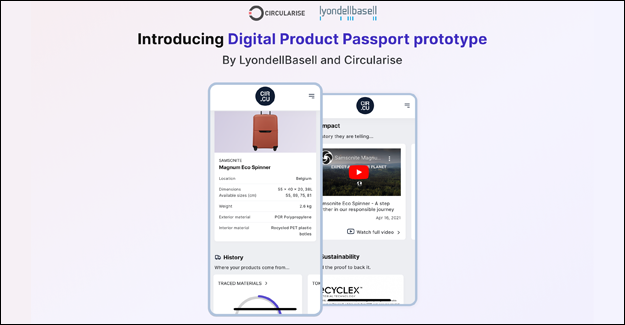

LyondellBasell, Together With 4 Value Chain Collaborators Introduces Digital Product Passport Solution Prototype

LyondellBasell has developed a prototype project for a Digital Product Passport (DPP) in collaboration with software provider Circularise and value chain collaborators Neste, QCP, Uponor and Samsonite. This LyondellBasell prototype uses Circularise’s traceability software to create a unique digital record or “digital twin” of a product, capable of detailing its environmental impact and recording changes in its physical lifecycle. With these features, digital product passports will help to enable circular economy processes by making it easier to gather and share product data while facilitating tracking along the value chain. “We are continuously looking for ways to innovate and support our customers with sustainable solutions that have a substantial impact up and down the value chain. This Digital Product Passport technology has the capability of delivering precise information about a product and provides insights into the product’s components and environmental impact as it moves through the value chain. It therefore also offers the possibility to better understand what can be done in the next part of the product life journey,” said Paula Sanabria Luque, Associate Director - Circular Polymer Solutions Europe at LyondellBasell. “In the future, the DPP will also give valuable information about greenhouse gasses. This can support everyone in the value chain in meeting their scope 3 emission goals”. “Digital product passports contain information associated with products to effectively track materials and their environmental impact. This aids companies to provide data-based sustainability information, and helps them to move towards more data driven circular innovation strategies,” said Jordi de Vos, Circularise’s co-founder. “The information in the DPP can be accessible through a unique digital ID which will always stay with the product. When entering a new stage in the production or recycling process the DPP is updated, providing traceability for circular business models. This is in line with the European Commission’s plans to require digital product passports in the near future, which would contain information about the composition of goods on the European market to help boost their chances of being reused and recycled and help consumers make more informed purchasing decisions.” A circular economy requires collaboration. That is why LyondellBasell brought in upstream and downstream value chain players to join the digital product passport pilot project, including: renewable and recycled feedstock supplier Neste, mechanical recycler QCP, building and infrastructure systems manufacturer Uponor, as well as luggage manufacturer Samsonite. This collaboration allowed the parties to better understand their supply chains and gain knowledge about the life cycle impact of products.

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.