UMI : The Rising Star In Sustainable Solutions For Process Houses

United Mizu Industries Pvt. Ltd. (UMI) is a well-established and growing engineering company. Led by a team of professionals, the company offers innovative turnkey Zero Liquid Discharge (ZLD) plants, focussed on generating profits from waste by utilising minimum energy. UMI manufactures the following products:

- Caustic Recovery Plants (CRP)

- Heat Recovery Unit (HRU)

- Salt Recovery Plant

- Multiple Effect Evaporator Plants (MEE),

- Mechanical Vapour Recompressor (MVR),

- Agitated Thin Film Dryers (ATFD)

- Solvent Recovery and Stripper Systems

Advantages

• Payback time is less than one year!

• No alkaline waste water from mercerizing machine

• Generation of hot water from waste energy

• Generation of soft water, the vapour condensate is slightly alkaline

• Recovery of surplus lye for wet-on-wet mercerizing

• No contamination of the heating steam

• Environmental protection: less chemicals for neutralization are needed

Multi effect evaporators

Forced Circulation Evaporator is used for concentrating high viscosity material and products with higher solids to achieve desired concentration. In this type of evaporator, the liquid is pumped through tube side of calandria at high velocity avoiding precipitation and fouling the liquid, then passed through vapour separator for separation of vapour. Concentrated liquid is continuously discharged from bottom of the vapour separator with pump.

Advantages

Advantages

• Payback time is less than one year!

• No alkaline waste water from mercerizing machine

• Generation of hot water from waste energy

• Generation of soft water, the vapour condensate is slightly alkaline

• Recovery of surplus lye for wet-on-wet mercerizing

• No contamination of the heating steam

• Environmental protection: less chemicals for neutralization are needed

Multi effect evaporators

Forced Circulation Evaporator is used for concentrating high viscosity material and products with higher solids to achieve desired concentration. In this type of evaporator, the liquid is pumped through tube side of calandria at high velocity avoiding precipitation and fouling the liquid, then passed through vapour separator for separation of vapour. Concentrated liquid is continuously discharged from bottom of the vapour separator with pump.

Advantages

- Fouling of tubes is minimised

- Designed for highest steam economy

- High recirculation is to be maintained inside the tubes by recirculation pump

- High TDS and viscous liquid concentration

- Rising Film Evaporator

- Low pressure drop

Mechanical Vapour Recompressor – UMI has developed portable pilot plant too for trials at client facilities.[/caption]

Heat Recovery System

With the increasing cost of energy, it is imperative to look at alternatives to save energy, leading to sustainable operations. Environmental impact also needs to be considered given the visible impacts of global warming.

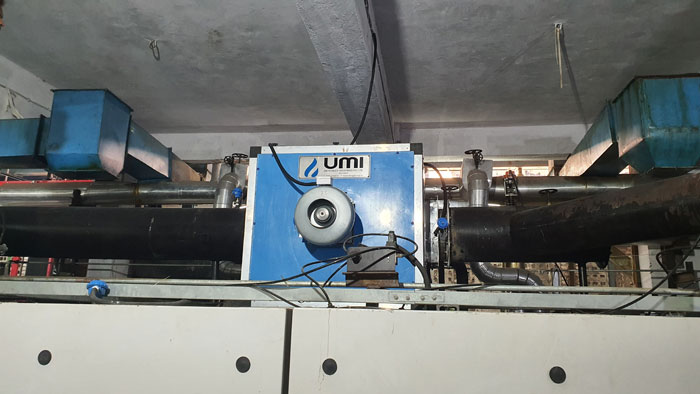

UMI is thus proud to introduce air-to-air heat recovery units for stenters and dryers, in keeping with the urgent need to conserve and reduce wastage of energy.

[caption id="attachment_24296" align="alignnone" width="700"]

Mechanical Vapour Recompressor – UMI has developed portable pilot plant too for trials at client facilities.[/caption]

Heat Recovery System

With the increasing cost of energy, it is imperative to look at alternatives to save energy, leading to sustainable operations. Environmental impact also needs to be considered given the visible impacts of global warming.

UMI is thus proud to introduce air-to-air heat recovery units for stenters and dryers, in keeping with the urgent need to conserve and reduce wastage of energy.

[caption id="attachment_24296" align="alignnone" width="700"] UMI’s heat recovery unit helps save thermal energy costs, and the environment[/caption]

In any process house, hot air stenter and dryers are the most energy consuming system. Apart from thermal energy required for evaporation of water during drying and finishing, considerable amount of energy is lost in the exhaust.

The solution

UMI’s heat recovery system recovers part of the energy in the hot air in the exhaust ducting before it is let off in the atmosphere. Significant amount of thermal energy is recovered by pre-heating the fresh air. This pre-heated fresh air is fed inside the stenter and dryer chambers. The exhaust air is partially cooled which helps considerably in reducing the global warming problem.

In a typical heat-setting operation, the fresh air at an ambient temperature of 38 degree Celsius get preheated to about 80-90 degree Celsius with the help of UMI’s heat recovery system. The pre-heated air at higher temperature enters in the chamber thereby reducing thermal energy consumption considerably.

Sustainability is achieved by maintaining consistency in operations. Performance is monitored with the help of PLC provided with the system.

Ease of operation and maintenance is ensured by hassle-free removal and cleaning of filter screens. Quick resetting the stenter for production is possible due to onsite cleaning of the heat recovery unit.

UMI’s heat recovery unit helps save thermal energy costs, and the environment[/caption]

In any process house, hot air stenter and dryers are the most energy consuming system. Apart from thermal energy required for evaporation of water during drying and finishing, considerable amount of energy is lost in the exhaust.

The solution

UMI’s heat recovery system recovers part of the energy in the hot air in the exhaust ducting before it is let off in the atmosphere. Significant amount of thermal energy is recovered by pre-heating the fresh air. This pre-heated fresh air is fed inside the stenter and dryer chambers. The exhaust air is partially cooled which helps considerably in reducing the global warming problem.

In a typical heat-setting operation, the fresh air at an ambient temperature of 38 degree Celsius get preheated to about 80-90 degree Celsius with the help of UMI’s heat recovery system. The pre-heated air at higher temperature enters in the chamber thereby reducing thermal energy consumption considerably.

Sustainability is achieved by maintaining consistency in operations. Performance is monitored with the help of PLC provided with the system.

Ease of operation and maintenance is ensured by hassle-free removal and cleaning of filter screens. Quick resetting the stenter for production is possible due to onsite cleaning of the heat recovery unit.

Textile Excellence

Subscribe To Textile Excellence Print Edition

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.