A New Green Solution For Dyeing Blue Denim

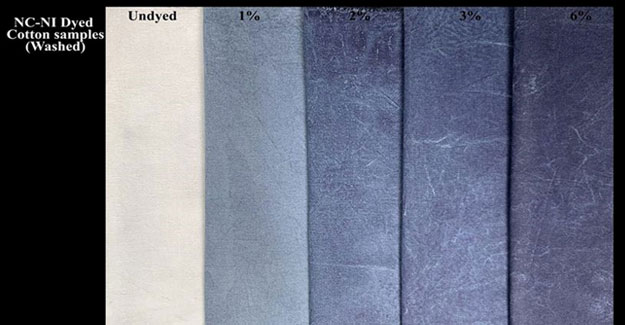

Whatever colour your clothes are, the process to make them that way is probably pretty toxic. According to the United Nations Environment Assembly, textile dyeing is the second largest water polluter in the world. And not only is fabric dyeing full of harmful chemicals, it's water-expensive: Your average pair of jeans takes up to 26 gallons (100 litres) of water to dye. In these days of fast fashion, our hunger for trendy clothes might be killing us — and a lot of other organisms and ecosystems all over the world. The denim industry alone uses over 45,000 tons (40,823 metric tons) of synthetic indigo a year, more than 84,000 tons (76,203 metric tons) of sodium hydrosulfite and 53,000 tons (48,080 metric tons) of lye, according to scientists at the University of Georgia. This adds up to a big environmental problem. However, a research team at the University of Georgia has worked out a solution to toxic denim dyeing that eliminates noxious chemicals from the denim dyeing process while using a fraction of the water. A green solution for blue The new denim dyeing method, detailed in the July 27, 2021, issue of the journal Green Chemistry, mixes cellulose nanoparticles made from wood pulp — a sugar called chitosan — with natural indigo dye (although the researchers believe synthetic dyes could also be used). This mixture creates a sort of gel that can be applied to the fabric a single time to yield an intense indigo colour, compared with the multiple dip process of conventional dyeing processes that require up to eight applications of dye to yield a dark shade. The chitosan essentially glues the pigment in place after the fabric dries, creating a sort of matrix of dye that coats the fibres of the denim. Because this process doesn't involve dissolving the indigo dye, no reducing agents are necessary, thus reducing the amount of water used in conventional dyeing methods by about 96%. Not only that, the process is non-toxic, the drying time for the chitosan dye is shorter and the new technique yields fabric of the same weight, thickness and overall feel as traditionally dyed denim. The new dyeing method can be used to create a variety of shades by varying the indigo formula. The dangers of denim dyeing Back in the 1700s, indigo — the plant that historically made denim that iconic blue colour — was a major export of the American colonies. These days, however, we dye our blue jeans with synthetic indigo pigment, which is why you can buy a pair of jeans for $15. But no matter whether the indigo is natural or synthetic, the process of pigment dyeing denim requires a strong reducing agent to make the dye dissolve in water. "The commercial technology for dyeing textiles uses aggressive chemicals," says Sergiy Minko, a co-author of the study and a professor in the College of Family and Consumer Sciences at the University of Georgia. "For denim, a strong, toxic reducing agent called sodium hydrosulfite is used. To make it soluble, some amount of this reducing agent is used in each stage of a repeating process — anywhere from five to 10 times, if they want to get an intense shade." Apart from the use of toxic reducing agents, denim pigmentation uses a huge amount of water. A pair of jeans can take up to 2,000 gallons (7,570 liters), if you consider the water it takes to grow the cotton, dye the fabric and manufacture the pants. Not only that, many of the chemicals involved in denim dyeing don't degrade in the environment. While the technology exists to filter the toxic chemicals out of the water before it hits a river or stream, many of the places in the world where garment production happens do not effectively remove the chemicals from the water before it contaminates waterways and ends up poisoning wildlife, people and crops.

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.