‘Building Competitive Advantage Rather Than Depending On Comparative Advantage Has Been ELGi's Successful Strategy'

ELGi Equipments is among the few Indian engineering companies that are truly global. For manufacturing world class air compressors, the company invests heavily in state-of-the-art technology, innovations, in downstream capabilities, and most importantly, in its people, bringing about a fruitful convergence between the company's philosophy and goals with the life goals of its employees. Managing Director Dr. Jairam Varadaraj, in an exclusive interview with Reena Mital, talks at length about ELGi's path to becoming the second largest air compressor manufacturer in the world by 2027.

Acquisition of Australian company F.R. Pulford & Sons Pty Ltd, a strong growth trend, and an ambition to become the world number two player in air compressor technology. What is the starting point to get there?

The starting point is very good. We have gone through a learning curve to face the challenges of global markets. We are in a stronger position today. Over the next 9-10 years, we expect a strong trajectory. We have put in a lot of preparatory work. In the first period, we will be in the flat end of the hockey stick curve, with a 15-18% revenue growth globally. It is difficult to visualise the inflection point, and as we grow we will learn what we need to do.

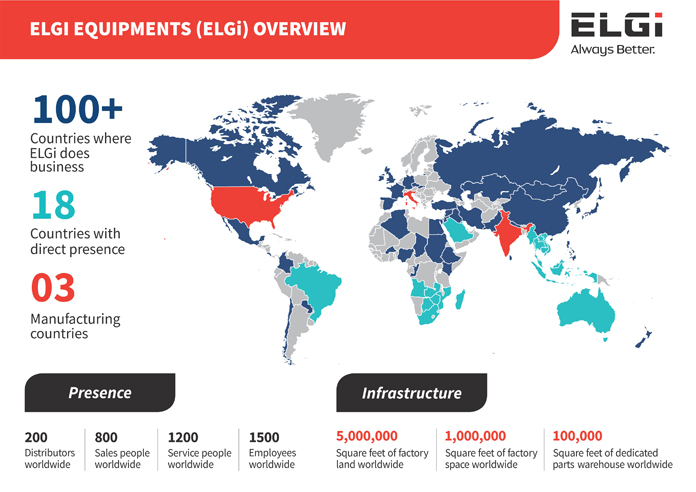

We have a realistic goal of becoming the number two player in the world by 2027. Currently, the number one player enjoys a turnover of US$ 5 billion, the second player is at US$ 1.8 billion, and we are at US$ 250 million. So we need to get to the second position. Now this is a significant step, which requires internal transformation of the organisation, and that is not easy.

So how do you plan to change internally?

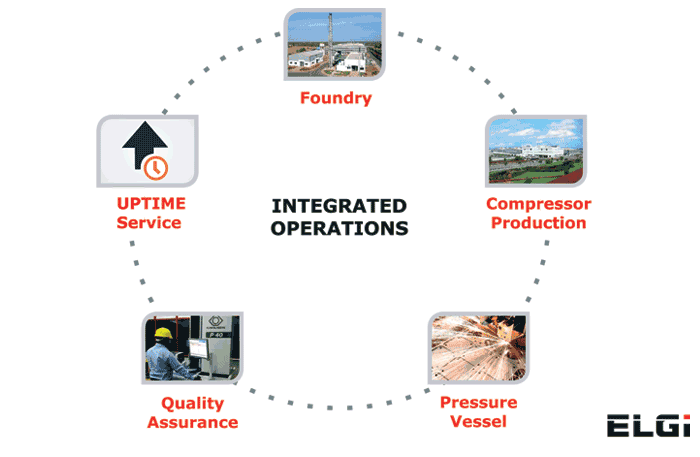

Broadly, we have categorised our operations into two dimensions - backend and front end. The backend is our state-of-the-art manufacturing capacities, the innovative technologies that we have developed, our foundry that is one of the best in the country. We spent 15 years building the technology, processes, logic, quality systems. We have reached a level of maturity to engage in international markets. Why did we do this? Because we realised quite early in the game that the tolerance level for failure of a made in India product is very low.

If a European product fails, it is forgiven. So we have to be better than our competitors. And we are, and this is on ongoing process.

The front end is a little different - it's not just about advertising, and creating product and brand awareness, but about creating brand experience. A brand experience not just for customers, but for the employees, the visitors and for everyone who comes across the brand. That is a complex process and involves people engagement.

Transforming people and processes to global standards does not happen easily. And more so in India. To give a comparison, Japan and Korea's trajectory was oriented towards being a global nation - so their policies, social institutions - were all geared towards that aim. In India, till the 1990s, we followed the principle of self-sufficiency, our industrial policies were inward looking, we did not build for the world, and we produced for a protected market.

That mindset, working ethos does not change overnight. Going back to the example of Korea, today the country represents a certain standard and quality - in products and people - engaging globally, while fiercely protecting their identity. We will need to go through this process.

You plan to manufacture in the US. Is that a competitive option, and a plan to be perceived as a global player?

We have reached a certain volume in the US that warrants manufacturing in that region to better service the customer. The market cannot be served effectively with just warehousing and inventories.

As a global company, we believe in having competitive advantage. We are a global company. Does that mean we just export? No. We have a world class brand that is recognised and respected by our customers. We don't build on the back of cheap Indian labour. We want Indian labour to be as expensive and productive as in the west.

To give an instance, a blue collar employee in our company earns Rs 6 lakh per annum. In Italy, we have a factory we provide the technology to, where the blue collar worker earns Rs 24 lakh, and is still profitable. So why can't Indians earn that much? Yes they can. We are designing a line in India which will be implemented next year, where the blue collar employee will earn the same as his European counterpart, and this line will be profitable.

We will then replicate this model in the US or Europe, and still stay profitable. We have thus created degrees of freedom in India to make Indians expensive. People have asked me why I am doing this, am I not responsible for generating employment. I can employ more people and get the work done, just as well, at lesser cost. I believe the government is responsible for employment generation.

I am responsible for generating value for the employment, raising the value of employment. Sure, low cost labour is India's comparative advantage, but ELGi does not rely on that. We rely on our competitive advantages that we have built and achieved over the years.

Can you tell us about your latest technological achievement in oil-free compressor?

Successful development of our oil-free compressor technology is a big achievement for us. It is a disruptive technology. We have nine installations in India. We will officially launch the product in Germany in April 2019. To give you a background, there are oil lubricated and oil-free compressors in the market. If an oil lubricated compressor works on an efficiency level of 100, oil-free compressor works on a level of 85. Price wise, if oil lubricated compressor costs 100, oil-free compressor costs 300.

We began working on the project seven years ago, to merge the two technologies, to produce oil-free compressor at the efficiency and price of an oil lubricated compressor.

We have achieved an efficiency level of 95, and have begun working on the next project of closing the 5% gap that exists between our oil-free compressor and an oil lubricated compressor. With our technology, the industry gains an efficiency level of 10% in oil-free compressor. We have achieved significant reduction in price too, which is 150, compared to 100 of oil lubricated compressor. We are confident that even if we cannot match the oil lubricated compressor price, we can still bring it down further. These two in itself are strong value propositions for the industry.

We have installed around nine machines in India in the last two months. These are in industries such as pharma, distilleries, normal industries, and importantly in foundries too, where oil-free compressors usually will not run. Ours is a sturdy technology, which will run in such dirty environments too.

How will the acquisition of Pulford's Australia benefit you?

Pulford's is among the largest distributors of industrial compressors in Australia. The acquisition is a means of giving customers better access to ELGi brands, products, services. Our strategy is to partner with service providers in the various regions, and not acquire manufacturing units or brands. We have sound manufacturing capabilities and technologies. We have a strong brand in ELGi. So our acquisitions and partnerships across the globe will be with distribution, sales and service companies so that we can give better access to our customers.

How are you positioned globally - in India, in the west, in Asia?

Our business is 50% India and 50% rest of the world. Out of that, 75% is Europe and USA. So India, Europe, USA are the three big geographies for us. We expect bigger chunk of revenue coming from Europe and America.

We have been in India for the last 15 years, we are a known and proven brand here. The difference is that we have much greater acceptance for ELGi in America and Europe, than in India. The Indian market was bombarded with mediocre products due to the license raj, and so when markets opened, we started importing foreign goods. So, we need to do things ten times better to overcome this image perception. How do we do it? We produce the most efficient compressors. We have a fundamental philosophy - when we sell something, we have absolute responsibility that it works. So we make a world class product and we offer unmatched service.

We began working on the project seven years ago, to merge the two technologies, to produce oil-free compressor at the efficiency and price of an oil lubricated compressor.

We have achieved an efficiency level of 95, and have begun working on the next project of closing the 5% gap that exists between our oil-free compressor and an oil lubricated compressor. With our technology, the industry gains an efficiency level of 10% in oil-free compressor. We have achieved significant reduction in price too, which is 150, compared to 100 of oil lubricated compressor. We are confident that even if we cannot match the oil lubricated compressor price, we can still bring it down further. These two in itself are strong value propositions for the industry.

We have installed around nine machines in India in the last two months. These are in industries such as pharma, distilleries, normal industries, and importantly in foundries too, where oil-free compressors usually will not run. Ours is a sturdy technology, which will run in such dirty environments too.

How will the acquisition of Pulford's Australia benefit you?

Pulford's is among the largest distributors of industrial compressors in Australia. The acquisition is a means of giving customers better access to ELGi brands, products, services. Our strategy is to partner with service providers in the various regions, and not acquire manufacturing units or brands. We have sound manufacturing capabilities and technologies. We have a strong brand in ELGi. So our acquisitions and partnerships across the globe will be with distribution, sales and service companies so that we can give better access to our customers.

How are you positioned globally - in India, in the west, in Asia?

Our business is 50% India and 50% rest of the world. Out of that, 75% is Europe and USA. So India, Europe, USA are the three big geographies for us. We expect bigger chunk of revenue coming from Europe and America.

We have been in India for the last 15 years, we are a known and proven brand here. The difference is that we have much greater acceptance for ELGi in America and Europe, than in India. The Indian market was bombarded with mediocre products due to the license raj, and so when markets opened, we started importing foreign goods. So, we need to do things ten times better to overcome this image perception. How do we do it? We produce the most efficient compressors. We have a fundamental philosophy - when we sell something, we have absolute responsibility that it works. So we make a world class product and we offer unmatched service.

In the west, customers buy on relationships they have with their distributors. In western markets, our strategy has been to work with leading distributors, to convince them that we are the best partner for them, because we make the most reliable product. This obviously brings down their service costs. We have grown exponentially in the US and Europe for this reason.

Asian markets are a different ball game altogether. Our growth in the US and EU is far higher than in Indonesia, Thailand, and other countries. Here the strategy is to go direct to the customer, the distributor is not the main source of sales. Asia is India-like in behaviour. Except that our brand is not as well known in Asia as in Europe and USA.

I would take China out of the equation. We entered this market six years ago. It's a tough market, we cannot take a global strategy and go to China. That is especially true for an Indian company. They are extremely brand conscious. European and American brand value is higher in China, compared to an Indian or even a Chinese brand. And then the expectation of pricing is not sustainable.

We realised that after five years there. We stopped manufacturing in China. We only do sales and service there. Focus is now US and Europe, which put together are far bigger than China, for ELGi. We will need a different strategy for China. Maybe by the time we become reasonably dominant in US and Europe, the aura of our brand will change, and become acceptable in China.

You are a successful Indian engineering company with your own proven technology that has made a mark in the international market. What is your message to other Indian engineering companies, who depend on JVs, technology tie-ups that eventually break down?

It is a question of your aspirations. If your aspiration is to be an Indian company, a JV can be good enough. But if you have ambitions to go global, you need to be independent, you cannot be tethered to someone else for technology or for global markets. There are very few truly global companies in India. Just because you buy a company in the west, does not make you global. For me a global company is a company that is truly agnostic to any one country's comparative advantage.

It has to be your technology, your brand, your distribution. That is a global organisation that is not dependent on selling cheap Indians. When your aspiration is global, you put that as the central requirement and build your organisation and strategies around it. Rather than say I am what I am, and then opportunistically grab what comes to you.

So that is basically where the Indian textile engineering industry lacks?

I started my career in the textile industry. We make components for the spinning industry. I have wondered why it is that Indians who own the bulk of the growing of cotton and bulk of spindles, have not driven innovations in this industry. It is the Swiss, the Japanese who own the conversion technologies.

A transformation in the Indian textile engineering industry will not happen overnight, you will have to make a 10-year consistent investment plan in technology, and follow your ambition.

You are putting up a line where your workers will earn as much as Europeans do. Do you think that concept can work in the textile industry too?

Look at our business. We are mechanical engineers. We are not into software where values are difficult to define. We are commodity driven business - based on prices of castings, motors, aluminium, etc. It's about how we add value to these commodities.

When I joined the company, our turnover was Rs 90 crore, and we had 2800 people on the shopfloor. Today our turnover is Rs 1880 crore and we have 335 people on shop floor. But we did not let our people go empty-handed. Whoever was not capable of being part of the ELGi dream or ambition, was given enough money, which was put in a public sector bank deposit. The interest from that matched their last take home salary.

Productivity improvement at ELGi is not done just by the white collar employees and thrust upon the blue collar employees. It is a process of building trust. We don't have unions and wage agreements. We have a commitment to our employees that their cost of living will be protected, no matter what the performance of the company. And that cost of living is calculated based on our own internal basket, which contains 340 items of consumption including things like haircuts, education fees, Wi-Fi, laptops, vacation, durables, and provisions. Our employees go to specified shops in Coimbatore where bulk of our employees live, get actual prices of the items, and the salaries are accordingly fixed. And it takes the management 15 minutes every year to do this exercise. Every five years, we change the standard of living. Our workers grow older, children graduate from school to college. We index all this. So we build a high amount of trust. When you present this dream and the way for achieving this is by adding more value to your work, we ensure improvement in productivity.

Coming back to the textile industry, is the industry willing to go through this process? ELGi's journey is now 24 years long. It doesn't happen in one financial year. You take your time, articulate your vision, and keep investing consistently towards it. You have to get over the inertia. Once you get over the inertia, the momentum picks up.

Your views on Make in India, Skills India, and Digital India programmes of the government.

Make in India sounds good, but needs a better definition. If it is Make in India for the world, which logically it should be - then all the trade policies, taxation policies, industrial policies, need to be built around that objective. Otherwise it's just a banner, and there is no integration of that statement of operationalising it where it matters.

Skilling India, this for me, is a mind boggling paradox. At the ELGi training institute, we take 60 students each year, from rural areas, from challenged families, we offer three years of training, pay stipend and give them the potential to get into ELGi and earn Rs 50000 a month. According to me, people should be clamoring for this. However, we have difficulty to get people. When we talk to youngsters, they are happier with flexible jobs in the unorganised sector, two days of housekeeping, two days of construction, no need to commit to eight hours a day, six days a week. And this is the thing with the younger generation, educated and otherwise.

When the government brings in the skill initiative, the underlying belief is that you will eventually opt for a permanent job. But there is a disconnect here. Skills have to be connected to jobs, and if the jobs are of a temporary nature, then skilling is a waste.

So, in these government programmes, I see bits and pieces of announcements, not the full picture.

ELGi wants to keep the Indian flag flying proudly at all times…

This is more of a brand building exercise, a demonstrator technology. If you've seen the flag at Connaught Place in Delhi, it is a 90 feet by 60 feet flag, which does not fly most of the time. We are in the air business, and we felt we can demonstrate that it can fly with low and sustainable energy. We have been successful with a 60 feet by 45 feet flag, which we will install in the next six months. We are still working on the 90 feet by 60 feet flag.

This is more of a brand building exercise. We have invested around Rs 2-2.5 crore in the project, we have three full-time engineers working on this. We hope the government will let us install this technology at our own cost on the Wagah border, where they are setting up this flag.

In the west, customers buy on relationships they have with their distributors. In western markets, our strategy has been to work with leading distributors, to convince them that we are the best partner for them, because we make the most reliable product. This obviously brings down their service costs. We have grown exponentially in the US and Europe for this reason.

Asian markets are a different ball game altogether. Our growth in the US and EU is far higher than in Indonesia, Thailand, and other countries. Here the strategy is to go direct to the customer, the distributor is not the main source of sales. Asia is India-like in behaviour. Except that our brand is not as well known in Asia as in Europe and USA.

I would take China out of the equation. We entered this market six years ago. It's a tough market, we cannot take a global strategy and go to China. That is especially true for an Indian company. They are extremely brand conscious. European and American brand value is higher in China, compared to an Indian or even a Chinese brand. And then the expectation of pricing is not sustainable.

We realised that after five years there. We stopped manufacturing in China. We only do sales and service there. Focus is now US and Europe, which put together are far bigger than China, for ELGi. We will need a different strategy for China. Maybe by the time we become reasonably dominant in US and Europe, the aura of our brand will change, and become acceptable in China.

You are a successful Indian engineering company with your own proven technology that has made a mark in the international market. What is your message to other Indian engineering companies, who depend on JVs, technology tie-ups that eventually break down?

It is a question of your aspirations. If your aspiration is to be an Indian company, a JV can be good enough. But if you have ambitions to go global, you need to be independent, you cannot be tethered to someone else for technology or for global markets. There are very few truly global companies in India. Just because you buy a company in the west, does not make you global. For me a global company is a company that is truly agnostic to any one country's comparative advantage.

It has to be your technology, your brand, your distribution. That is a global organisation that is not dependent on selling cheap Indians. When your aspiration is global, you put that as the central requirement and build your organisation and strategies around it. Rather than say I am what I am, and then opportunistically grab what comes to you.

So that is basically where the Indian textile engineering industry lacks?

I started my career in the textile industry. We make components for the spinning industry. I have wondered why it is that Indians who own the bulk of the growing of cotton and bulk of spindles, have not driven innovations in this industry. It is the Swiss, the Japanese who own the conversion technologies.

A transformation in the Indian textile engineering industry will not happen overnight, you will have to make a 10-year consistent investment plan in technology, and follow your ambition.

You are putting up a line where your workers will earn as much as Europeans do. Do you think that concept can work in the textile industry too?

Look at our business. We are mechanical engineers. We are not into software where values are difficult to define. We are commodity driven business - based on prices of castings, motors, aluminium, etc. It's about how we add value to these commodities.

When I joined the company, our turnover was Rs 90 crore, and we had 2800 people on the shopfloor. Today our turnover is Rs 1880 crore and we have 335 people on shop floor. But we did not let our people go empty-handed. Whoever was not capable of being part of the ELGi dream or ambition, was given enough money, which was put in a public sector bank deposit. The interest from that matched their last take home salary.

Productivity improvement at ELGi is not done just by the white collar employees and thrust upon the blue collar employees. It is a process of building trust. We don't have unions and wage agreements. We have a commitment to our employees that their cost of living will be protected, no matter what the performance of the company. And that cost of living is calculated based on our own internal basket, which contains 340 items of consumption including things like haircuts, education fees, Wi-Fi, laptops, vacation, durables, and provisions. Our employees go to specified shops in Coimbatore where bulk of our employees live, get actual prices of the items, and the salaries are accordingly fixed. And it takes the management 15 minutes every year to do this exercise. Every five years, we change the standard of living. Our workers grow older, children graduate from school to college. We index all this. So we build a high amount of trust. When you present this dream and the way for achieving this is by adding more value to your work, we ensure improvement in productivity.

Coming back to the textile industry, is the industry willing to go through this process? ELGi's journey is now 24 years long. It doesn't happen in one financial year. You take your time, articulate your vision, and keep investing consistently towards it. You have to get over the inertia. Once you get over the inertia, the momentum picks up.

Your views on Make in India, Skills India, and Digital India programmes of the government.

Make in India sounds good, but needs a better definition. If it is Make in India for the world, which logically it should be - then all the trade policies, taxation policies, industrial policies, need to be built around that objective. Otherwise it's just a banner, and there is no integration of that statement of operationalising it where it matters.

Skilling India, this for me, is a mind boggling paradox. At the ELGi training institute, we take 60 students each year, from rural areas, from challenged families, we offer three years of training, pay stipend and give them the potential to get into ELGi and earn Rs 50000 a month. According to me, people should be clamoring for this. However, we have difficulty to get people. When we talk to youngsters, they are happier with flexible jobs in the unorganised sector, two days of housekeeping, two days of construction, no need to commit to eight hours a day, six days a week. And this is the thing with the younger generation, educated and otherwise.

When the government brings in the skill initiative, the underlying belief is that you will eventually opt for a permanent job. But there is a disconnect here. Skills have to be connected to jobs, and if the jobs are of a temporary nature, then skilling is a waste.

So, in these government programmes, I see bits and pieces of announcements, not the full picture.

ELGi wants to keep the Indian flag flying proudly at all times…

This is more of a brand building exercise, a demonstrator technology. If you've seen the flag at Connaught Place in Delhi, it is a 90 feet by 60 feet flag, which does not fly most of the time. We are in the air business, and we felt we can demonstrate that it can fly with low and sustainable energy. We have been successful with a 60 feet by 45 feet flag, which we will install in the next six months. We are still working on the 90 feet by 60 feet flag.

This is more of a brand building exercise. We have invested around Rs 2-2.5 crore in the project, we have three full-time engineers working on this. We hope the government will let us install this technology at our own cost on the Wagah border, where they are setting up this flag.

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.